Le 17/01/2024

written by Alice O.

How do I use a cutting wire to install my wrapping ?

For clean, precise wrapping finishes, follow our advice.

For a wrapping partial or total wrapping, cutting remains a key element.

To ensure clean, professional-looking cuts, cutting wire is your best friend!

Find out in this article how to use it correctly.

Why use cutting wire?

The cutting wire is an accessory used by the majority of professionals and hobbyists. wrapping. It offers a number of advantages:

- Easy to use: Whether you're a professional or a beginner, anyone can use cutting wire. We'll explain the method a little further down in this article.

- It won't damage the bodywork: Cutting your wrapping directly on the bodywork with a cutter means running the risk of scratching it. With the cutting wire, there's no risk! 😉

- It offers precise finishes: once removed, the wire will give a clean, crisp cut, whatever the curves and angles to be followed. ✂️

- For a professional result: Clean finishes are a sign of quality, as if you've just come from a professional. 👌

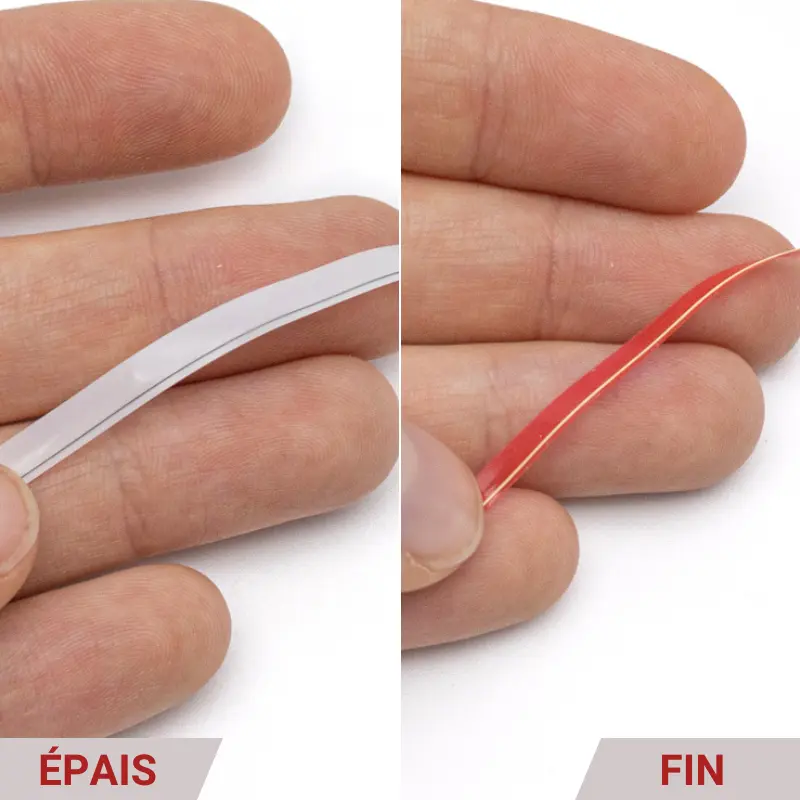

What's the difference between thin and thick cutting wire?

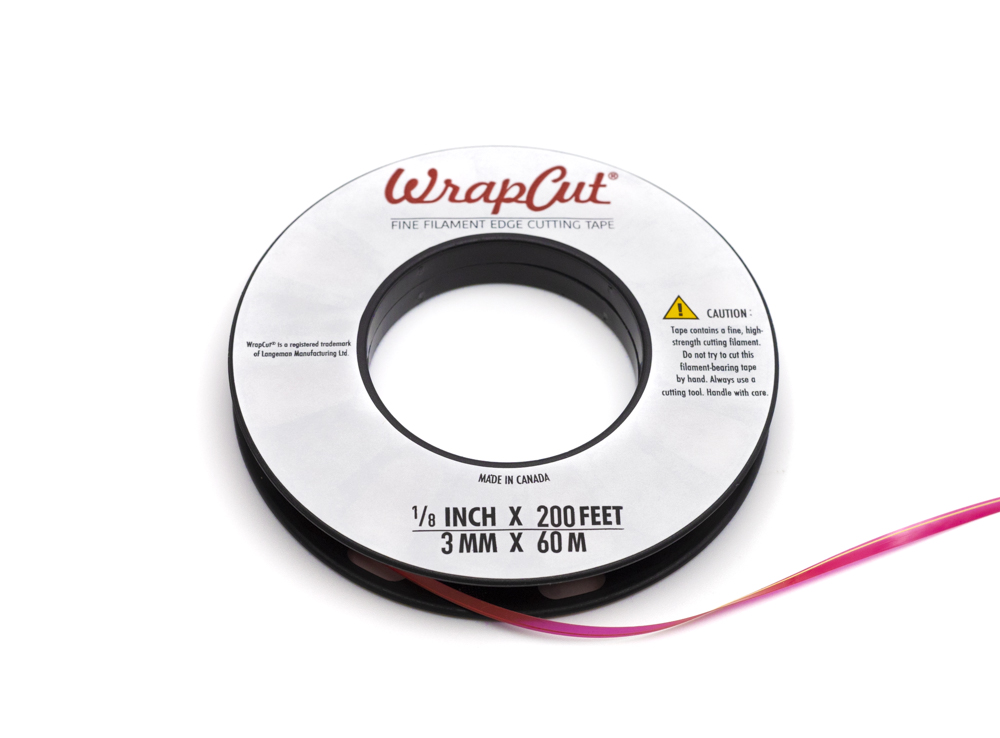

Fine cutting wire is suitable for thin to medium thickness adhesives, such as wrapping auto. It will produce precise cuts with ease.

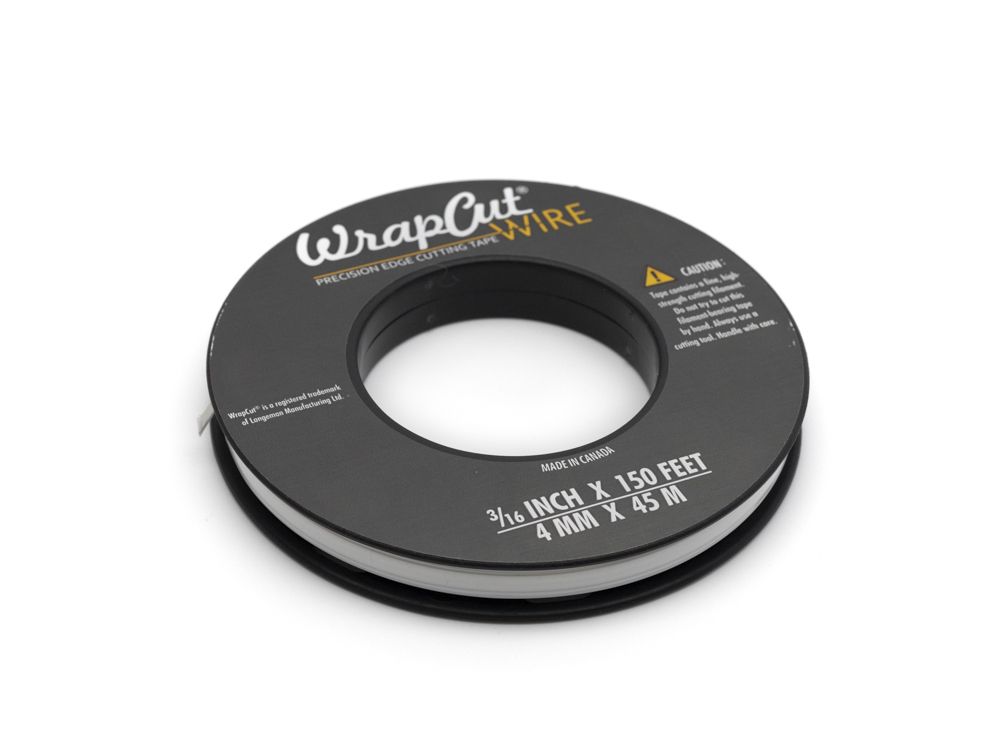

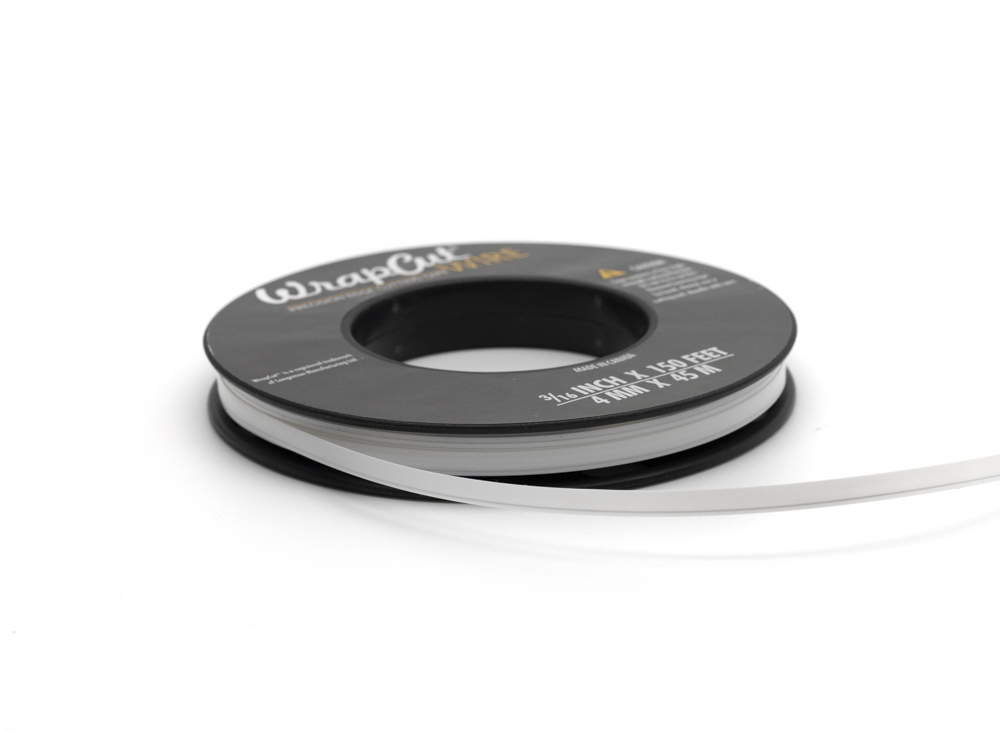

Thick cutting wire is used for thicker adhesives, such as PPF (body protection film) or marking film. Its thread is stronger, generally metallic, to pass through thicker materials.

Thick or thin, the method of using the cutting wire remains the same in both cases.

Our selection of cutting wire for wrapping

Thick or thin, long or shorter, choose your favourite accessory for a successful installation of wrapping.

How do I use my cutting wire?

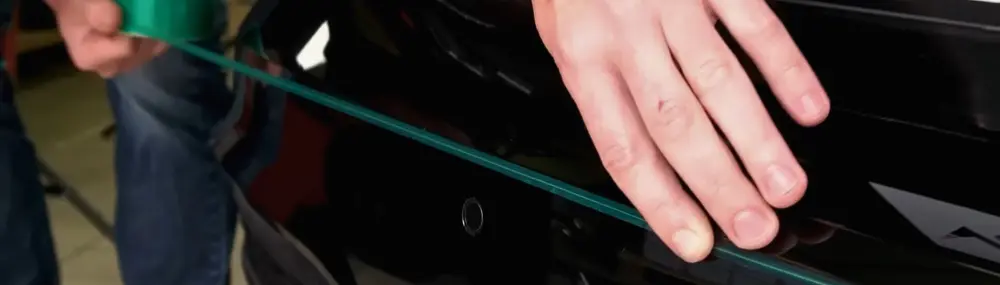

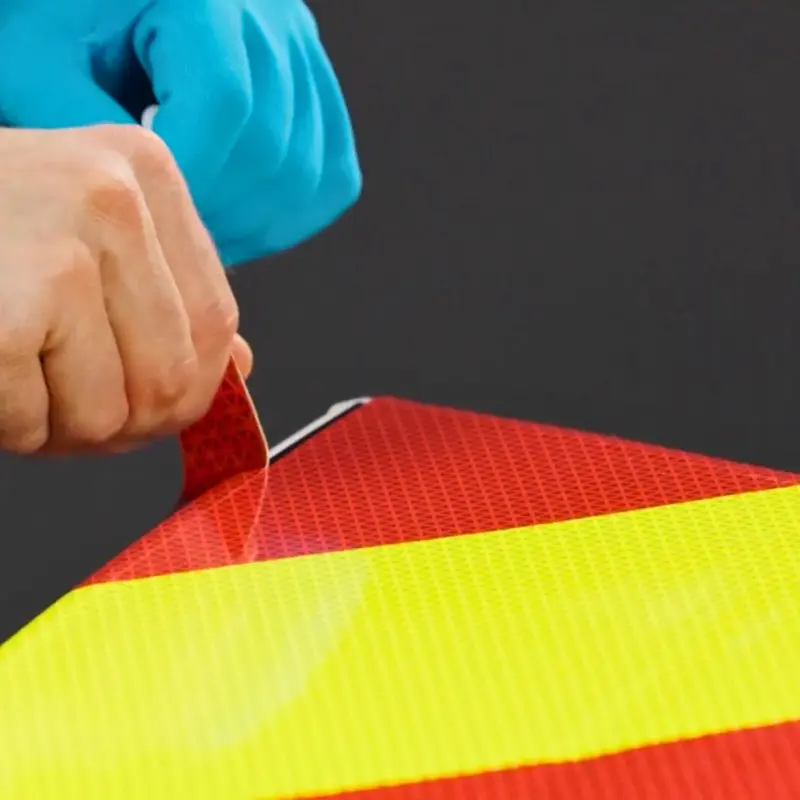

The cutting wire is installed before the wrapping.

- Make sure the bodywork is thoroughly clean.

- Take along your spool of cutting wire.

- Leave about 5 centimetres of overhang, so that you can pull it out at the end.

- Position the wire all along the area to be cut. The wire should be positioned where you want wrapping to stop.

- Be sure to maintain a little tension on the wire as you apply it: it needs to lie flat and taut on the bodywork.

- Press a little along the entire length of the film, so that it adheres well to the surface.

- Place your piece of wrapping on top, and lay it down like a classic wrapping .

- Iron the cut-outs to ensure that wrapping adheres well to the thread.

- To make the cut, take up the 5 cm you left at the start. Separate the wire from its adhesive using pliers or scissors.

- Pull on the wire while holding the holder firmly in place. The wire should pull out of the holder, but the holder should not move.

And that's all there is to it!